ASSIGNMENT 1: GASKET RECREATION

The goal of the assignment is to introduce some of the basic skills needed to manufacture mechanical components in the EPIC workshop.

The learning objectives are:

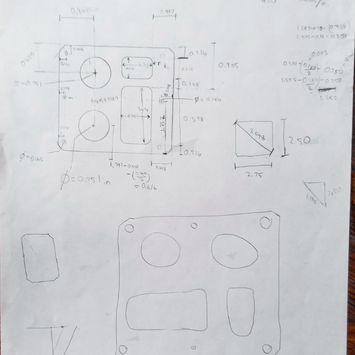

To make accurate measurements of the features of a mechanical component

To produce dimensioned sketches that serve as a basis for the creation of a CAD model

To get acquainted with the use of the GibbsCAM software for the manufacture of machine components on a CNC mill.

An aluminum block with several machined features was assigned. Among these are four pockets of different shapes and sizes, four threaded holes and two locating pins. The task is to produce a 1/16" thick PVC gasket that will fit on top of the block, allowing unrestricted access to all of its features. The alignment of the gasket will be determined by the locating pins.

*Please click on pictures (below) to enlarge and show more details*

Project Debrief: